Upravljanje naporima

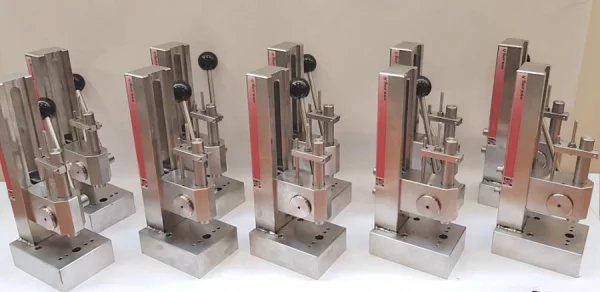

> for Manual and Pneumatic Presses

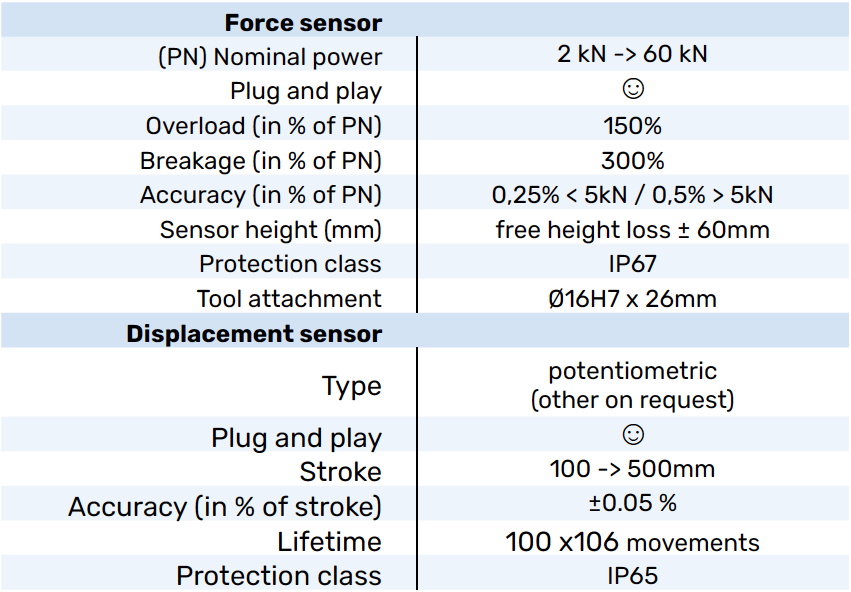

EMG offers all types of force/ displacement monitoring thanks to force and displacement sensor solutions adapted to each need, for 100% parts control.

It is the quality guaranteed by the monitoring of industrial processes:

> Permanent quality control

> Product process control

> Total traceability

> Monitoring the production

The quality assurance goes through a permanent process check.

The EMG presses, equipped with the force and / or displacement sensor allowing production of compliant parts from the beginning of the production process.

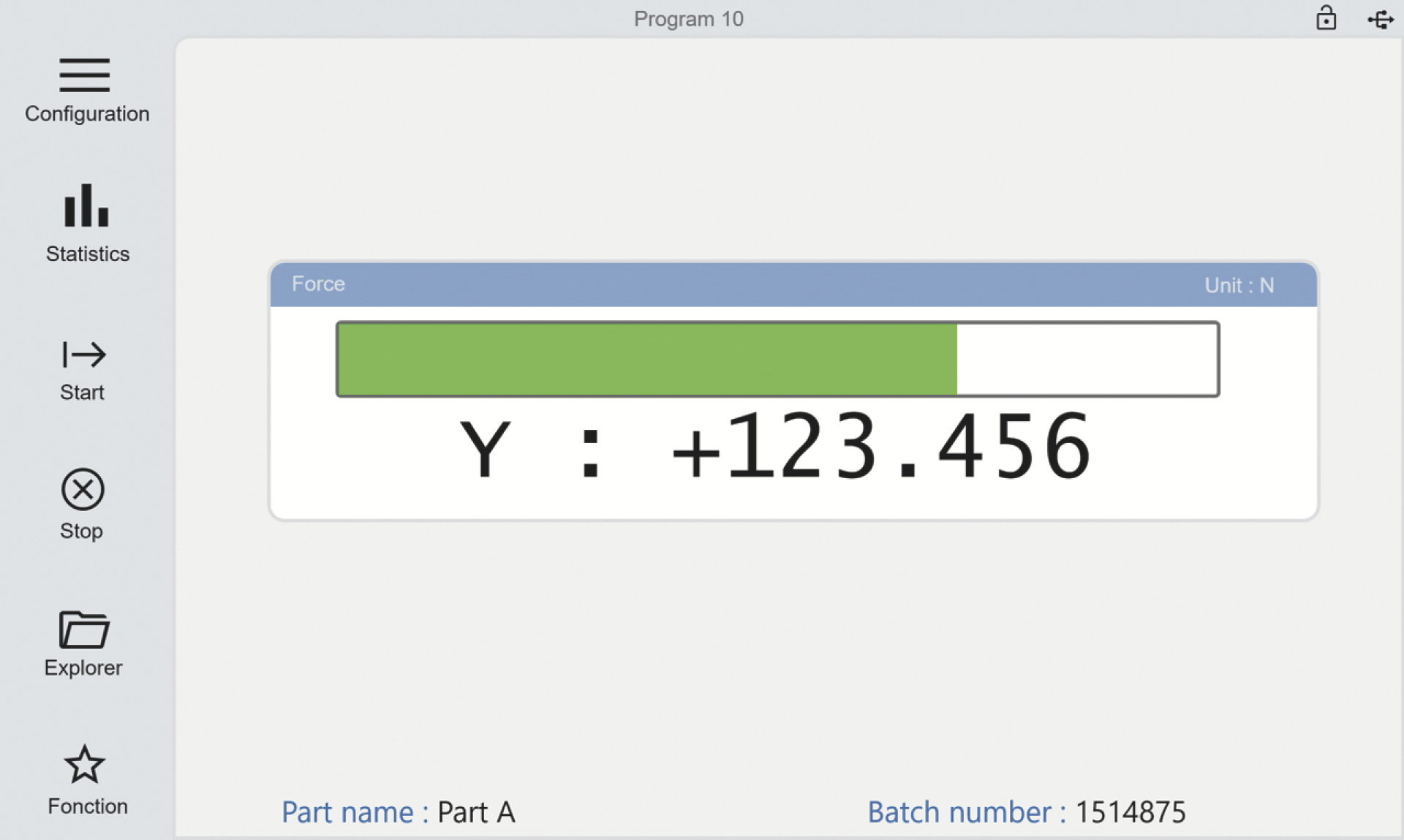

The detection of anomalies is immediate if the requested parameters are not reached, the monitoring unit delivers an «OK» or «NOK» message by means of an optical display, a sound signal, or by locking the press in position.

This signal allows the operator to immediately isolate the defected part.

The information is stored in the control unit and can be exported to a PC for analysis, statistics or archiving.

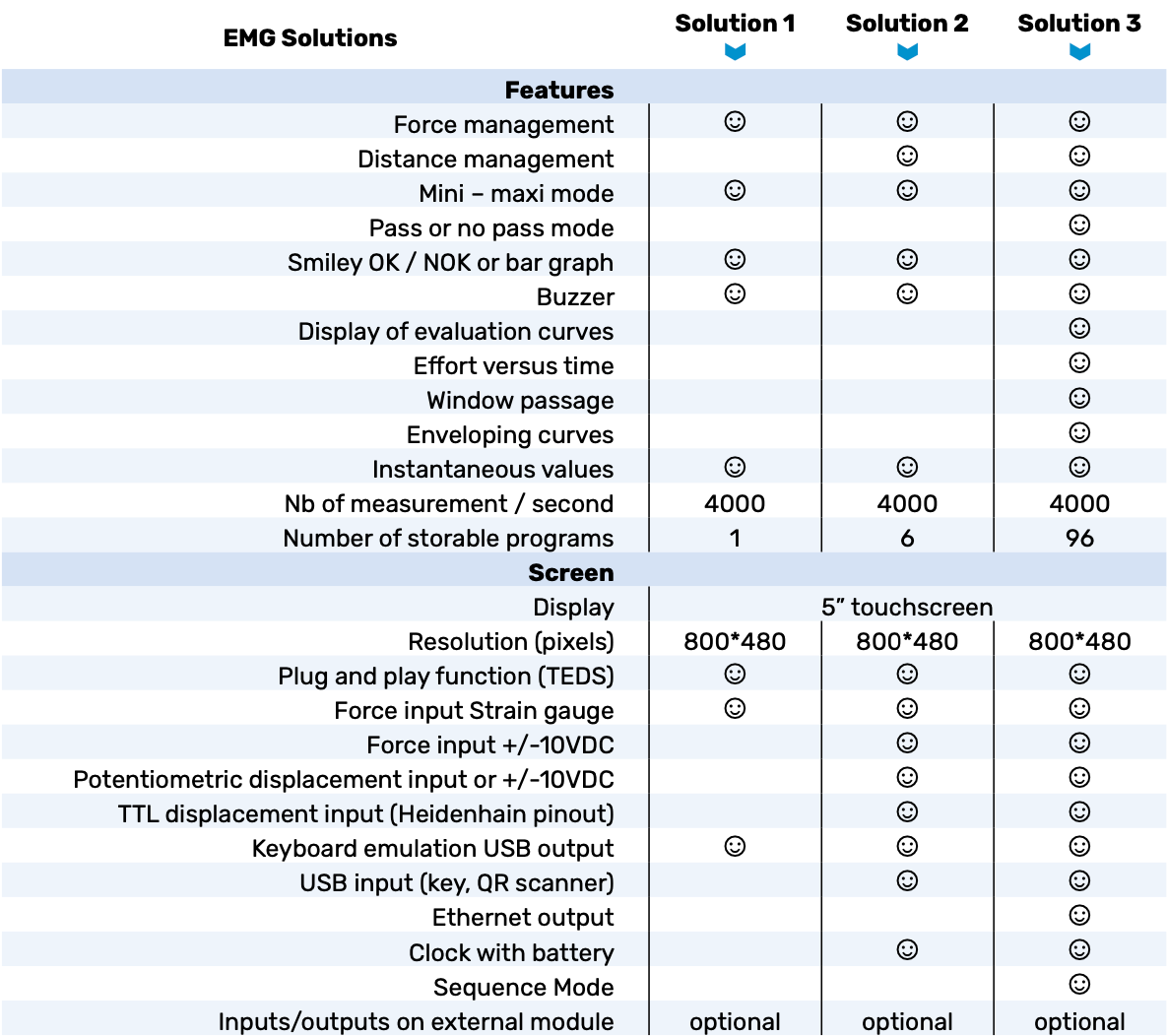

Three standard solutions exist in the range.

> Specific solutions can be proposed according to customer needs

Solution 1

> Force + thresholds

> Thresholds mini / maxi

Solution 1 makes it possible to evaluate the force instantaneously or by pre-setting a minimum and maximum force. A green or red smiley or a bargraph, coupled with a buzzer, will indicate the smooth running of the press cycle. Peak values are also available.

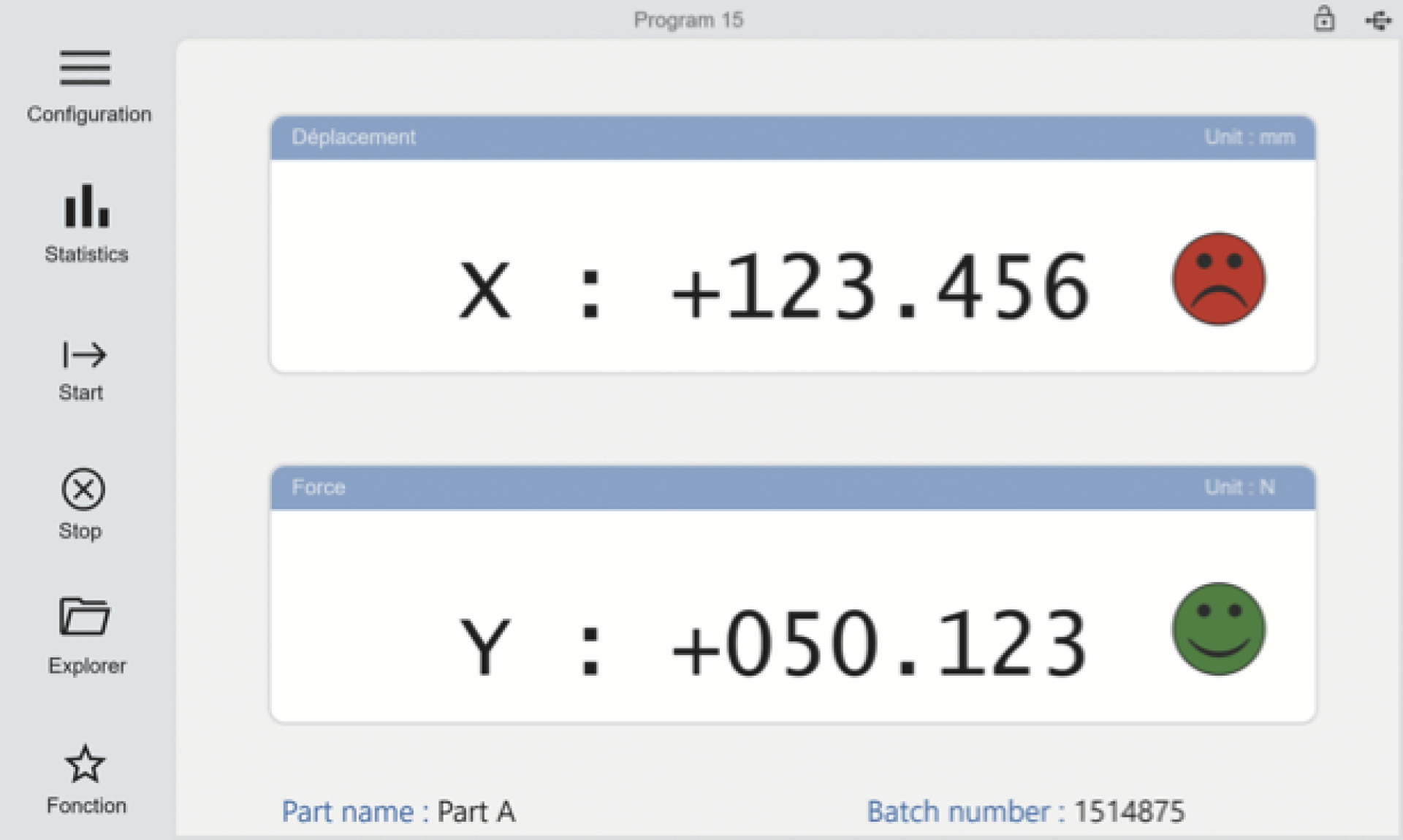

Solution 2

> Force

> Diplacement

> Thresholds mini / maxi

Solution 2 makes it possible to evaluate the force and the displacement instantaneously or by pre-setting a force and a minimum and maximum stroke. A green or red smiley or a bargraph, coupled with a buzzer, will indicate the smooth running of the press cycle. Peak values are also available.

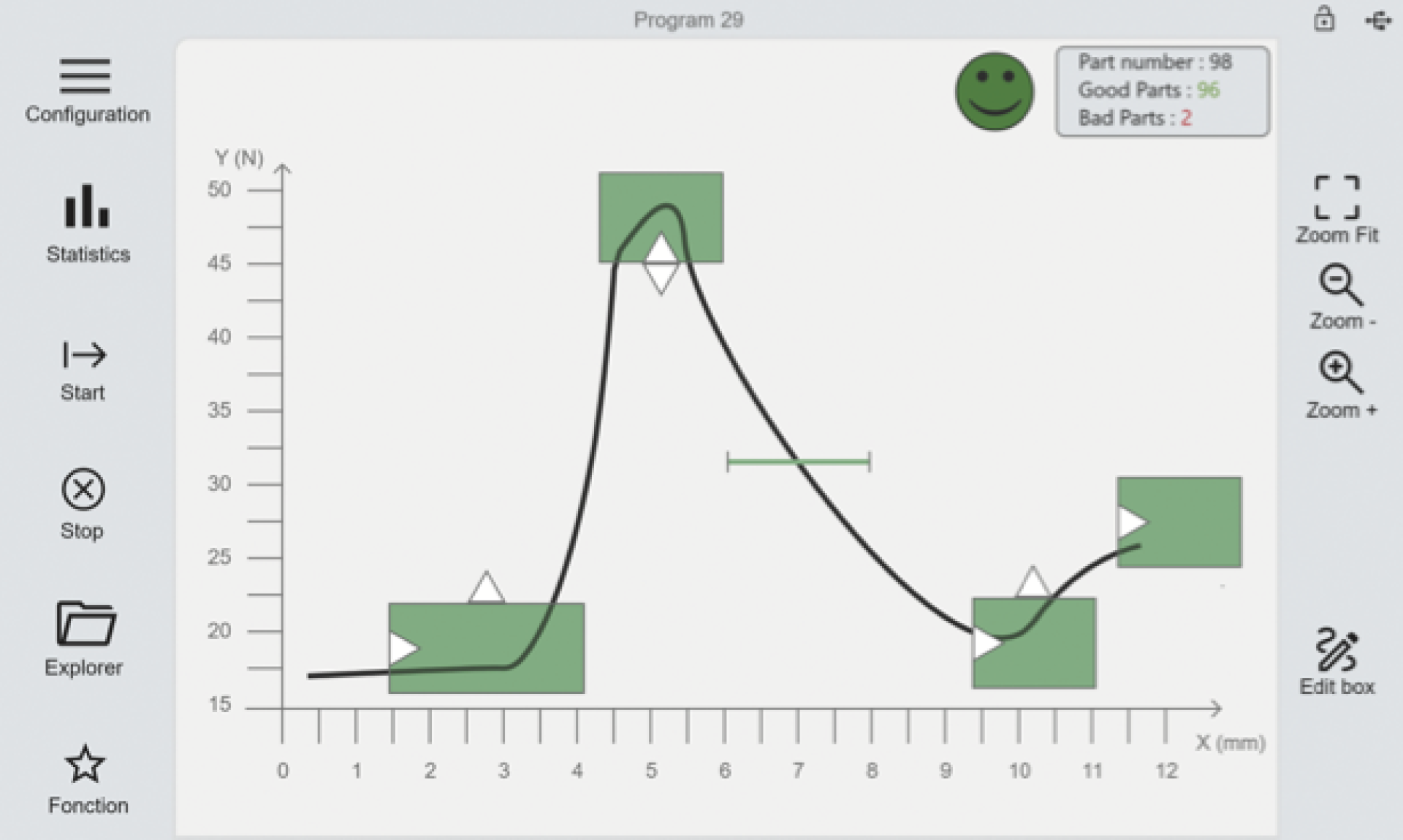

Solution 3

> Force

> Displacement

> Curves

Solution 3 makes it possible to evaluate the force and the displacement by setting either thresholds, windows or enveloping curves. The evaluation curve will instantly appear on the screen. A green or red smiley, coupled with a buzzer, will indicate that the press cycle is running smoothly.

TABLE OF CHARACTERISTICS